A ribbon blender is commonly used for mixing powders, small granules, and occasionally small amounts of liquid. When loading or filling a ribbon blender, the goal should be to optimize mixing efficiency and ensure uniformity, rather than just aiming for the maximum fill capacity. The effective fill level of a ribbon blender depends on several factors, such as the material properties and the shape and size of the mixing chamber. Therefore, it is not possible to provide a fixed percentage or quantity for how much a ribbon blender can be filled.

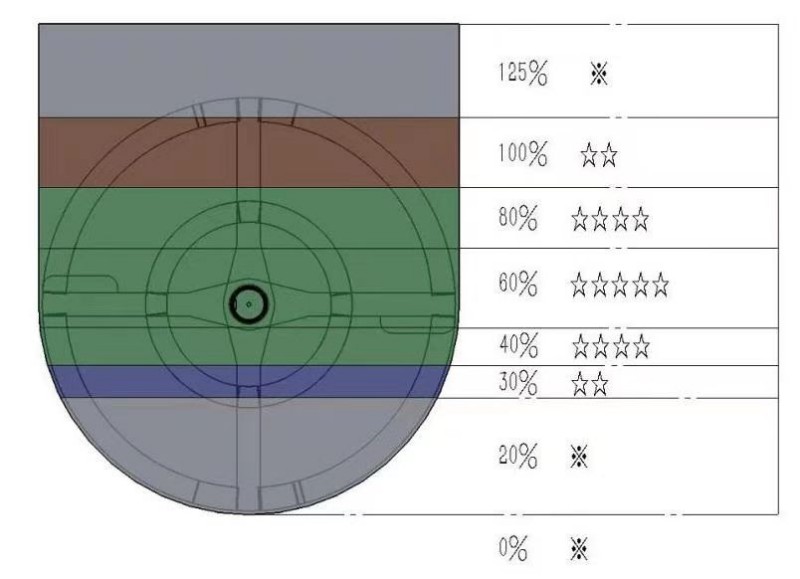

In practical operation, the optimal fill level is usually determined through experimentation and experience, based on the material’s characteristics and mixing requirements. The following graph illustrates the relationship between fill level and mixing performance. Generally, the right amount of filling ensures that the materials come into full contact during mixing, preventing uneven distribution or overloading of the equipment due to excessive filling. Therefore, when filling a ribbon blender, it’s crucial to find a balance that not only guarantees an effective mixing process but also maximizes the use of the equipment’s capacity, rather than just focusing on the maximum possible fill.

Based on the graph below, we can draw several conclusions for the ribbon blender: (assuming the material properties, as well as the shape and size of the mixing tank, remain constant).

Red: inner ribbon; Green is outer ribbon

A: When the fill volume of a ribbon blender is below 20% or exceeds 100%, the mixing effect is poor, and the materials cannot reach a uniform state. Therefore, filling within this range is not recommended.

*Note: For most ribbon blenders from different suppliers, the total volume is 125% of the working volume, which is labeled as the machine model. For example, a TDPM100 model ribbon blender has a total volume of 125 liters, with an effective working volume of 100 liters.

B: When the fill volume ranges from 80% to 100% or 30% to 40%, the mixing effect is average. You can extend the mixing time to achieve better results, but this range is still not optimal for filling.

C: A fill volume between 40% and 80% is considered optimal for a ribbon blender. This ensures both mixing capacity and effectiveness, making it the preferred range for most users. To estimate the loading rate:

- At 80% fill, the material should just cover the inner ribbon.- At 40% fill, the entire main shaft should be visible.

D: A fill volume between 40% and 60% achieves the best mixing effect in the shortest time. To estimate 60% fill, about a quarter of the inner ribbon should be visible. This 60% fill level represents the maximum capacity for achieving the best mixing results in a ribbon blender.

Media Contact

Company Name: SHANGHAI TOPS GROUP CO., LTD

Email: Send Email

Country: China

Website: https://www.topspacking.com/